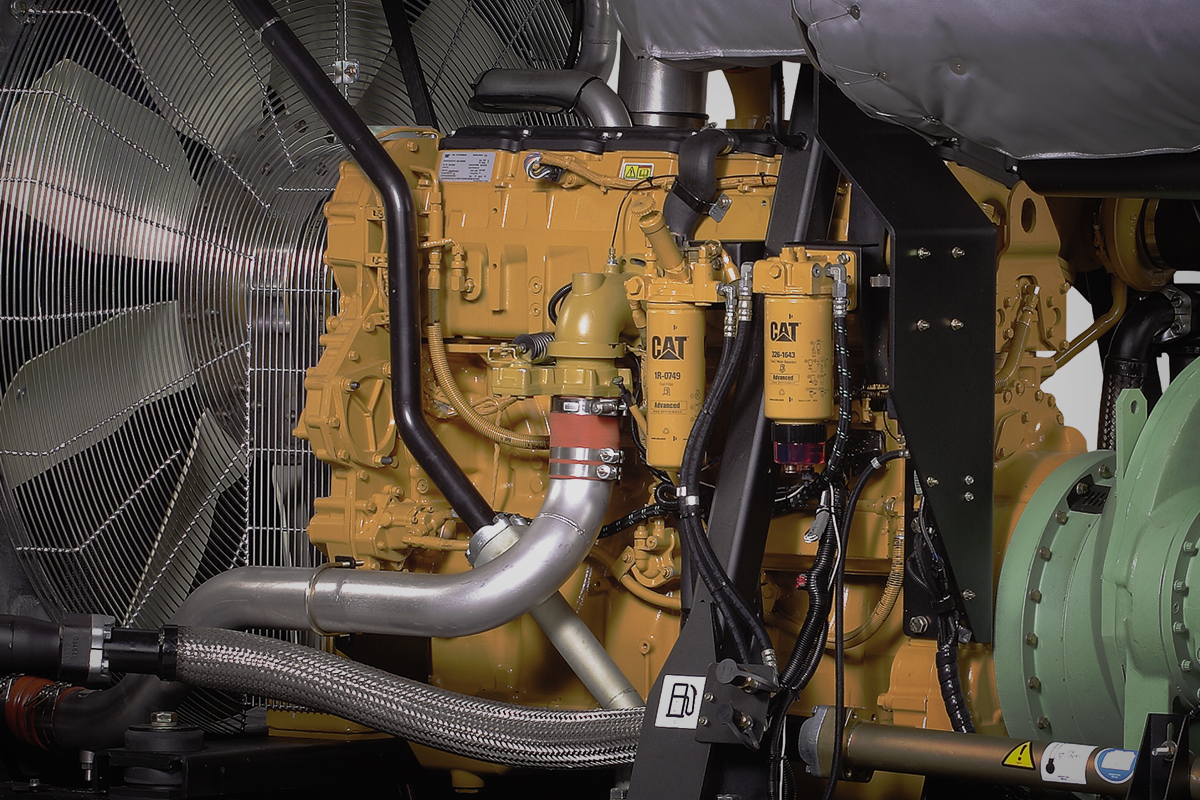

In previous installments of this blog, we have discussed not only industrial air compressor basics and their application, but also sizing and upkeep in industrial settings. While this subject is of great importance, and will be continually covered in future articles, consideration should also be given to other components of the air system that affect the usefulness of compressed air as an industrial energy source.

All industrial air compressors have the same basic principle of operation – they draw in ambient air and increase pressure by reducing the empty space between molecules. By doing this, the compressor not only increases air pressure, but also increases the concentration of any other substances that are present. Foreign materials that are drawn in with the ambient air (like water vapor, dust, fumes or aerosols) are concentrated at higher levels when the air is compressed and often can be detrimental to pneumatic processes and machinery.

For this reason, many industrial compressed air systems are equipped with dedicated equipment to clean and dry the compressed air stream. This equipment ensures that compressed air quality is suitable for its end use. Compressed air dryers, filters and condensate management systems all perform this function, and are often as important to an air system as the compressor itself. Equipment of this type is commonly referred to as “Air Treatment.”

Three primary types of compressed air contaminants

There are three primary types of compressed air contaminants as described by the International Standards Organization in their specification ISO 8573.1. These contaminant types are: water (or water vapor), solid particulate and oil. In this article, we will discuss the presence of water in compressed air systems, and the equipment that is commonly used to remove it.

Water

Water is a contaminant that is always present in compressed air systems. The concentration of ambient humidity during the compression process, combined with a sharp rise in temperature due to the heat of compression, causes all industrial compressors to discharge air at 100% saturation. The water vapor in compressed air will begin condensing into liquid as it travels through the pipe and cools. Because liquid water can corrode metal components and damage expensive industrial equipment, it is often removed from compressed air immediately after it leaves the compressor to protect the rest of the air system from its harmful effects.

Liquid water can be removed by moisture separators that utilize centrifugal motion to separate water droplets from the air stream. This liquid is then expelled from the system using a drain valve. However, water vapor cannot be removed by a moisture separator. Water vapor is often considered a contaminant in compressed air, because it has the potential to condense into liquid in the future. In order to effectively remove water vapor, a dedicated compressed air dryer must be utilized. Several

dryer technologies are used throughout the industry for this purpose – each with its own advantages and limitations. The most common types are Refrigerated Dryers and Regenerative Dryers.

Refrigerated Dryers

Refrigerated Dryers are commonly used in industrial and commercial settings, and often provide an affordable and effective solution for removing water from a compressed air system. They operate as their name suggests – by using a refrigeration circuit to decrease the temperature of the compressed air. When air temperature is decreased, its capacity to hold water vapor is also decreased. Thus, when air passes through a refrigerated dryer, a significant portion of its laden water vapor is condensed into liquid. This liquid water is then collected in a moisture separator, and expelled through a drain valve.

These dryers are commonly used because they provide an adequate solution for many industrial facilities at relatively low cost. However, there are some limitations to the application of refrigerated dryers. For example, refrigerated dryers cool the air in order to remove moisture. Therefore, their lowest pressure dewpoint is limited by the temperature at which water will freeze. Accordingly, refrigerated dryers are generally rated to produce pressure dewpoints around +38°F to avoid freezing. Similarly, the performance of refrigerated dryers can be greatly affected by ambient conditions. High ambient heat and poor ventilation exert a heavier workload on refrigeration systems, and cause the performance of refrigerated dryers to decline. These limitations must be accounted for when refrigerated dryers are sized and selected for a given application.

Regenerative Dryers

Regenerative Dryers pass compressed air through a media bed to remove water vapor. These units employ the properties of certain chemicals that have a high affinity to attract water molecules. Common chemicals used in regenerative dryer media beds are activated alumina, molecular sieve and silica gel. Regenerative dryers are capable of drying air much more thoroughly than refrigerated dryers, and can produce pressure dewpoints as low as -100°F.

These units are often used in applications where compressed air quality is of the utmost importance. Chemical manufacturing, oil & gas refining, medical applications and power plant systems often include regenerative air dryers. Additionally, regenerative air dryers are commonly used in outdoor applications where extremely high or low temperatures are possible, as they are less sensitive to ambient conditions than refrigerated dryers.

While regenerative dryers produce lower pressure dewpoints than refrigerated dryers, and are generally more robust, they come with a unique set of considerations. First, regenerative dryers are more expensive to own and operate than refrigerated dryers. They not only carry a higher initial purchase price, but also reduce the overall capacity and efficiency of the systems in which they are installed.

Normally, regenerative dryers are configured with two media beds. At any given time, one bed is drying, while the other bed is regenerating (or purging the moisture that has been picked up during the drying process.) During regeneration, the dryer actually consumes compressed air. For this reason, regenerative dryers must be selected carefully, as to not under supply a given application. Additionally, regenerative dryers decrease overall system efficiency by using compressed air for purging.

When to Employ External Heater or Dryer Technologies

Various technologies can be utilized to reduce the amount of air that these dryers use for regeneration (such as external heaters or blowers). However, each added feature will increase the initial purchase price of the dryer, so end users often employ these technologies only when the long-term efficiency gains outweigh the increase in initial cost.

In future articles, we will explore how additional air treatment equipment is used to combat the other forms of compressed air system contamination (particulate and oil). Additionally, we will cover the basics of air treatment sizing and selection.