OIL-FREE AIR COMPRESSORS

SRL Series Oil Free Scroll Air Compressor

OIL FREE AIR RELIABLY, EFFICIENTLY AND QUIETLY

Built on Hitachi engineering, the SRL Series represents advanced scroll compressor technology to meet your oil-free compressed air needs — today and tomorrow.

Maximizing efficiency means more than just having an efficient air compressor. All SRL Series compressors feature built-in logic to help utilize the air compressors most efficiently — which not only saves wear and tear on the compressor but also provides energy savings — which saves you money!

Certified Class 0 Oil-Free Air

SRL Exclusive Scroll and Pump Design

Integrated Design for Maximum User Benefits

Quiet Operation — as low as 48 dB(A)

Models vary by region. Please contact your Sullair sales representative for more details.

FLOW

5.7-129.3 cfm

.16-3.66 m³/min

POWER

2 – 44 hp

1.5 – 33 kW

PRESSURE

120 – 145 psi

8.3 – 10 bar

Features & Benefits

SRL Exclusive Scroll and Pump Design

- Patented scroll wrap design with labyrinth seal provides superior performance and reliability

- Proprietary tip seal reduces air leakage while extending service intervals

- Normal maintenance can be completed without disassembling the pump

Integrated Design for Maximum User Benefits

- Certified Class 0 oil-free air

- Highly efficient cooling

- Multi-stage cooling reduces ambient temperature out

- Receiver tank helps dissipate heat while reducing compressor starts/stops

- Air pressures to 145 PSIG

- Extremely quiet

- Sound levels as low as 48 dB(A)

- Full enclosure standard

- Mechanical and electrical vibration isolation

- Designed to be placed at the point of air need

- Compact design reduces floor space needed

- Maintenance-friendly

- Easy accessibility for inspection and maintenance

Models & Specs

Simplex

- SRL1.5 – 2 hp (1.5 kW), 120 psi, 5.7 cfm*

- SRL2.2 – 3 hp (2.2 kW), 120 – 145 psi, 8.5 cfm*

- SRL3.7 – 5 hp (3.7 kW), 120 psi, 14.1 cfm*

- SRL5.5 – 7.5 hp (5.5 kW), 120 – 145 psi, 21.2 cfm*

Multiplex

- SRL7.5 – 10 hp (7.5 kW), 122 – 145 psi, 30.2 cfm*

- SRL11 – 15 hp (11 kW), 122 – 145 psi, 43.1 cfm*

- SRL16.5 – 22 hp (16.5 kW), 122 – 145 psi, 64.6 cfm*

- SRL22 – 30 hp (22 kW), 122 – 145 psi, 86.2 cfm*

- SRL33 – 44 hp (33 kW), 122 – 145 psi, 129.3 cfm*

*cfm at lowest pressure rating

Original products designed by Hitachi Industrial Equipment Systems Co., Ltd

DSP Series Oil Free Rotary Screw Air Compressor

CERTIFIED CLASS 0 Oil FREE AIR. OPTIMIZED FOR ENERGY EFFICIENCY.

The DSP Series brings advanced oil-free operations right where it is needed: your facility!

Built on Hitachi engineering, the DSP is designed to supply oil-free air reliably and efficiently— today and tomorrow.

- Innovative Air End Design

- Patented Oil Mist Remover

- Motorized Isolation Valve

FLOW

117 – 1303 cfm

3.3 – 36.9 m³/min

POWER

125 psi

8.6 bar

PRESSURE

30 – 300 hp

22 – 240 kW

Features & Benefits

Innovative Air End Design

- Patented taper rotor design optimized for efficiency

- Stainless steel coating robotically applied to rotors in both 1st and 2nd stages provides superior corrosion resistance and durability

- Patented PTFE-free rotary coating designed for long life

- Coating specifically engineered to help ensure rotor tolerances remain consistent — maximizing discharge capacity over the life of the unit

- Stator housing coated to provide additional corrosion protection

Patented Oil Mist Remover

- An environmentally friendly solution to recapture gearcase oil mists

- Helps ensure oil-free air compression

- Recycles gearcase oil to reduce oil top offs needed

- Helps promote a cleaner production environment

Motorized Isolation Valve

- Automatically closes compressed air discharge when DSP shuts off — protecting the compressor from condensate backflow

Package Designed to Optimize Energy Efficiency and Oil-Free Operation

- VSD models feature a Patented No Inlet Valve Design

- Eliminates negative pressure at unloading — helping increase shaft seal reliability

- Fixed speed models feature patented 3- or 5-way solenoid valve

- Interstage air purging

- Provides energy savings when unloading

- Patented High Pre-Cooler Design

- Redundant cooler helps prevent thermal fatigue and cooler failure

- Helps reduce moisture content in compressed air

Key Features

- Wye-Delta or VSD Starter

- Phase Monitor

- Altitude Capacity: up to 9000 feet

- Oversized motor options available for peak usage needs

Warranty Information

- All DSP Series Compressors feature a 3-year package warranty

Integrated Design for Maximum User Benefits

- Certified Class 0 oil-free air

- Highly efficient cooling

- Multi-stage cooling reduces ambient temperature out

- Receiver tank helps dissipate heat while reducing compressor starts/stops

- Air pressures to 145 PSIG

- Extremely quiet

- Sound levels as low as 48 dB(A)

- Full enclosure standard

- Mechanical and electrical vibration isolation

- Designed to be placed at the point of air need

- Compact design reduces floor space needed

- Maintenance-friendly

- Easy accessibility for inspection and maintenance

Models & Specs

60 Hz

Fixed Speed

- DSP2209AY – 30 hp (22 kW), 125 psig (8.6 barg), 117 cfm (3.3 m³/min)

- DSP3009AY – 40 hp (30 kW), 125 psig (8.6 barg), 141 cfm (4.0 m³/min)

- DSP3709AY – 50 hp (37 kW), 125 psig (8.6 barg), 166 cfm (4.7 m³/min)

- DSP4509AY – 60 hp (45 kW), 125 psig (8.6 barg), 230 cfm (6.5 m³/min)

- DSP5509AY – 75 hp (55 kW), 125 psig (8.6 barg), 272 cfm (7.7 m³/min)

- DSP7509AY – 100 hp (75 kW), 125 psig (8.6 barg), 392 cfm (11.1 m³/min)

- DSP9009AY – 125 hp (90 kW), 125 psig (8.6 barg), 544 cfm (15.4 m³/min)

- DSP11009AY – 150 hp (110 kW), 125 psig (8.6 barg), 611 cfm (17.3 m³/min)

- DSP13210AY – 175 hp (132 kW), 125 psig (8.6 barg), 742 cfm (21.0 m³/min)

- DSP14510AY – 200 hp (145 kW), 125 psig (8.6 barg), 805 cfm (22.8 m³/min)

- DSP16010AY – 215 hp (160 kW), 125 psig (8.6 barg) 894 cfm (25.3 m³/min)

- DSP20010AY – 250 hp (200 kW), 125 psig (8.6 barg), 1169 cfm (33.1 m³/min)

- DSP24010AY – 300 hp (240 kW), 125 psig (8.6 barg), 1296 cfm (36.7 m³/min)

- DSP4509WY – 60 hp (45 kW), 125 psig (8.6 barg), 236 cfm (6.7 m³/min)

- DSP5509WY – 75 hp (55 kW), 125 psig (8.6 barg), 279 cfm (7.9 m³/min)

- DSP7509WY – 100 hp (75 kW), 125 psig (8.6 barg), 399 cfm (11.3 m³/min)

- DSP9009WY – 125 hp (90 kW), 125 psig (8.6 barg), 551 cfm (15.6 m³/min)

- DSP11009WY – 150 hp (110 kW), 125 psig (8.6 barg), 622 cfm (17.6 m³/min)

- DSP13210WY – 175 hp (132 kW), 125 psig (8.6 barg), 770 cfm (21.8 m³/min)

- DSP14510WY – 200 hp (145 kW), 125 psig (8.6 barg), 837 cfm (23.7 m³/min)

- DSP16010WY – 215 hp (160 kW), 125 psig (8.6 barg), 925 cfm (26.2 m³/min)

- DSP20010WY – 250 hp (200 kW), 125 psig (8.6 barg), 1169 cfm (33.1 m³/min)

- DSP24010WY – 300 hp (240 kW), 125 psig (8.6 barg), 1303 cfm (36.9 m³/min)

60 Hz

Variable Speed

- DSP3709AV – 50 hp (37 kW), 125 psig (8.6 barg), 162 cfm (4.6 m³/min)

- DSP5509AV – 75 hp (55 kW), 125 psig (8.6 barg), 272 cfm (7.7 m³/min)

- DSP7509AV – 100 hp (75 kW),125 psig (8.6 barg), 385 cfm (10.9 m³/min)

- DSP9009AV – 125 hp (90 kW), 125 psig (8.6 barg), 544 cfm (15.4 m³/min)

- DSP11009AV – 150 hp (110 kW), 125 psig (8.6 barg), 611 cfm (17.3 m³/min)

- DSP5509WV – 75 hp (55 kW), 125 psig (8.6 barg), 283 cfm (8.0 m³/min)

- DSP7509WV – 100 hp (75 kW), 125 psig (8.6 barg), 403 cfm (11.4 m³/min)

- DSP9009WV – 125 hp (90 kW), 125 psig (8.6 barg), 551 cfm (15.6 m³/min)

- DSP11009WV -150 hp (110 kW), 125 psig (8.6 barg), 622 cfm (17.6 m³/min)

- DSP16009WV – 215 hp (160 kW), 125 psig (8.6 barg), 925 cfm (26.2 m³/min)

- DSP24009WV – 300 hp (240 kW), 125 psig (8.6 barg), 1303 cfm (36.9 m³/min)

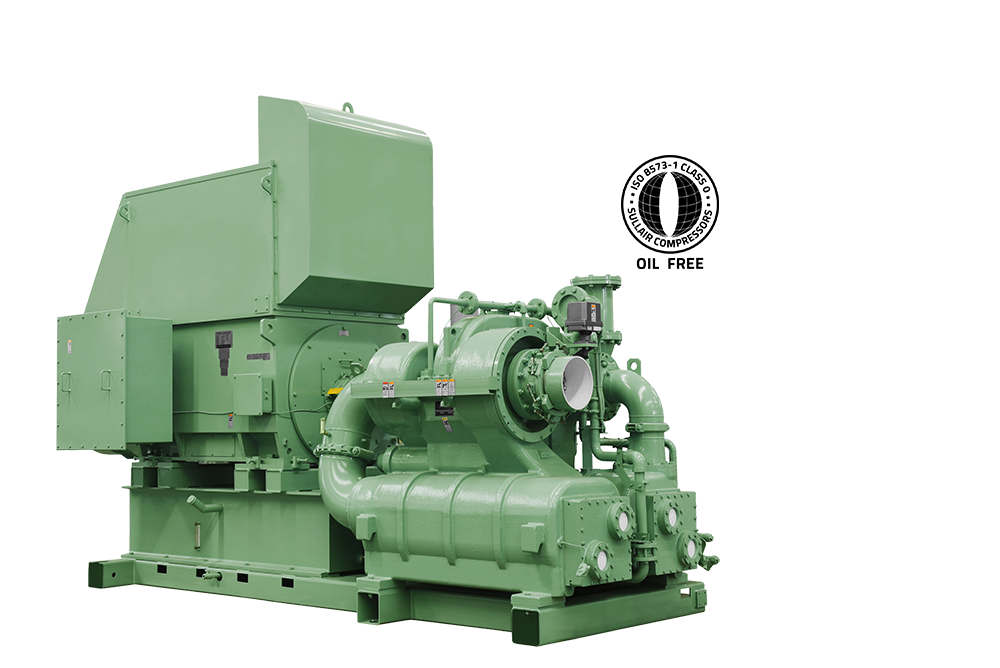

T-series Oil Free Centrifugal Air Compressors

EFFICIENT AERODYNAMICS. LOW MAINTENANCE.

Sullair Centrifugal T-Series compressors rely on a simple design—which not only reduces the potential for mechanical loss, but also simplifies maintenance and operation.

A robust, time-proven design helps Sullair Centrifugal compressors achieve unparalleled reliability and durability while providing Class 0 oil free air.

- Energy Efficiency

- Low Maintenance

- Ease of Operation

FLOW

POWER

PRESSURE

Features & Benefits

Ease of Use

- Advanced PLC Control System

- Non-Contacting Internal Components

- Anti-Reverse Rotation Main Shaft Oil Pump

Energy Efficiency

- Inlet Guide Vane/IGV

- High-Powered Impellers

- Diffusers

Stability and Vibration Reduction

- Single Piece Gear Box with Integrated Coolers

- Tilting Pad Journal Bearings

- Thrust Collars

Low Maintenance and Maximum Reliability

- Power Coupling

- Easily Accessible Coolers

- Aerodynamic Inlets

- Labyrinth Shaft Seals

- Bull Gear Bearings

Models & Specs

- T2 – 175 to 300 hp (125 to 230 kW), 500 to 1645 cfm, 60 to 130 psi

- TX – 325 to 535 hp (245 to 400 kW), 1050 to 2470 cfm, 60 to 145 psi

- TRA – 275 to 675 hp (210 to 500 kW), 1175 to 2900 cfm, 60 to 160 psi

- TRE – 400 to 1500 hp (300 to 1120 kW), 1750 to 6450 cfm, 20 to 230 psi

- T3 – 525 to 1875 hp (390 to 1400 kW), 2075 to 8525 cfm, 20 to 145 psi

- TRX – 900 to 2300 hp (670 to 1715 kW), 5300 to 11,750 cfm, 60 to 145 psi

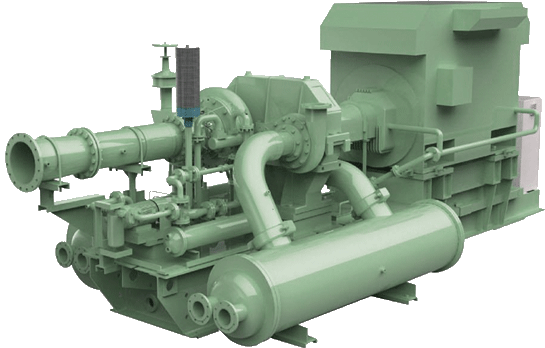

f-series Oil Free Centrifugal Air Compressors

EFFICIENT AERODYNAMICS. LOW MAINTENANCE.

f-series centrifugal compressors are high performance, custom-designed compressors to meet your specific needs. The f-series takes flexibility, power, and pressure to a higher level. f-series compressors are available in both packaged and non-packaged options, with compression available from single stage up to four stages.

All Sullair Centrifugal compressors rely on a simple design — which not only reduces the potential for mechanical loss but also simplifies maintenance and operation.

- Energy Efficiency – The optimal combination of components — from specially designed titanium impellers to tilting pad journal bearings – help Sullair centrifugal compressors operate with high efficiency which results in lower power consumption.

- Low Maintenance – The simple design means fewer moving parts. Because many of the components have a very low potential for wear, ongoing maintenance is significantly reduced. The horizontally split gearbox bearing, along with a split bearing and seal design, offers easy and convenient access to maintenance items: all moving parts can be checked by simply removing the gear box cover.

- Ease of Operation – Sullair Centrifugal Compressors are designed to be installed — and run. The compressor is equipped with many features that are packaged as standard — minimizing installation time.

FLOW

POWER

Features & Benefits

- Inlet Guide Vane (IGV)

- Gear Box

- Power Coupling

- Coolers

- Aerodynamic Inlets

- Advanced PLC Control System

- Multiple modes for different applications. Allen-Bradley or Siemens controls are standard on all models

Standard f-series packages

- 1200 to 118,000 scfm (33.98 to 3341.39 m³/min)

- 15 to 725 psig (1 to 50 bar)